Industries

We are not just a vendor – we are your Industry Partner with practical strategies to maximize efficiency, profitability, safety, and quality assurance for all types of business such as Truck and Trailer, Rail, Agriculture, Vehicle (Bus/Coach), and Aerospace.

We are ready to assist with your next project, product order, service and maintenance, or general inquiry to help you maintain the integrity of your brand.

Truck & Trailer

The truck and trailer industry plays a vital role in providing goods and services across many market sectors. From truck and trailer chassis and subframe assemblies to many truck cab and trailer fasteners, our expansive range of tooling and fastening solutions are geared to meet the needs of repair facilities and OEMs across North America.

The Manitoba truck/trailer sector showcases some of Canada’s leaders in grain and gravel trailer manufacturing, truck body and box fabricators, collision repair facilities, truck modification including day-cab conversions, and food truck outfitters.

Applifast ships its tooling and fastening solutions all over Canada and the United States to a large range of industries and manufacturers including aluminum and steel hopper trailers such as tri-axle, super B, and tandem.

Whatever your truck or trailer need is, Applifast has got you covered offering a wide range of name-brand solutions for any type or configuration of truck or trailer such as but not limited to aluminum and steel flatbed drop decks, trailers, b-trains, hoppers, flats, scissor neck, dump, walking floor, and low beds. Applifast is a senior Canadian Master Distributor for all major OEM heavy duty truck/trailer rivets and installation tools including Huck®, Avdel, and POP.

Rail

Canadian railways move over 100 million passengers and more than $320 billion worth of goods in Canada each year. Strength in the rail industry is essential, from railcars, tracks and engines to wheel assembly, service, and material removal. Expectations are sure to be exceeded through utilization of Applifast tooling and fastening solutions.

Not only is Winnipeg one of the two Canadian cities having three Class 1 railways, it also features rail access to the northern seaport of Churchill. One railroad company has its key repair facility located in Winnipeg which supplies freight car wheel sets, truck and refurbished freight car components, and maintenance equipment such as frogs and switch points. The facility is the maintenance centre for a large portion of the locomotive fleet as well.

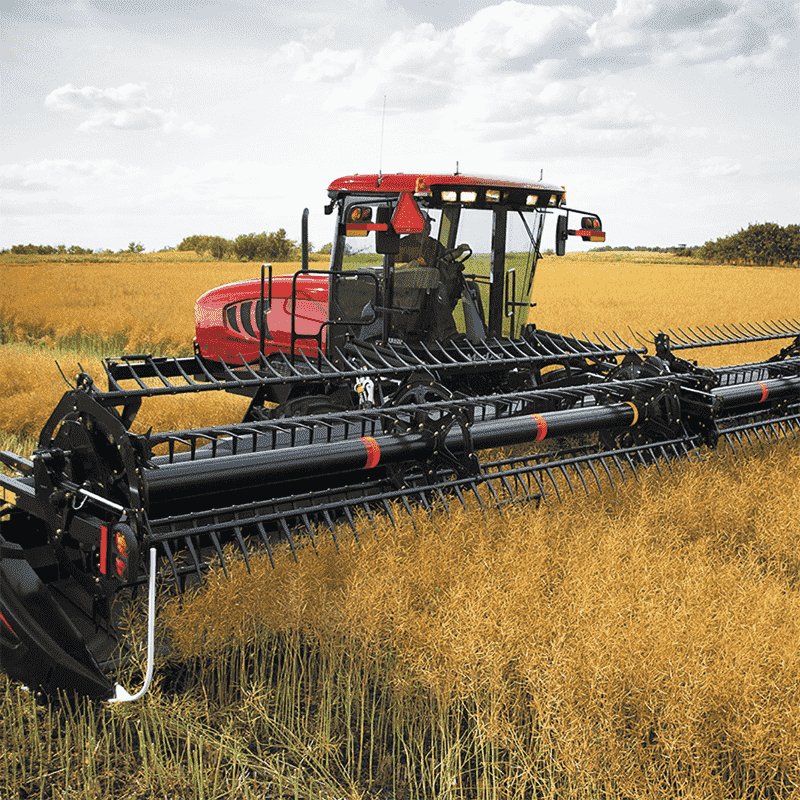

Agriculture

Manufacturers of harvesting equipment, tractors, trailers, and grain handling technology, including bins, belt conveyors, and augers, contribute to the rapid growth in Canadian technology exports and agribusiness manufacturing. Tools and fasteners supplied by Applifast generate improved quality, increased productivity, and higher-level safety to any agricultural manufacturing project, whether large or small.

Many agriculture industry manufacturers of seeding, spraying, harvesting and grain handling equipment in Canada’s prairie provinces have proven Applifast as a comprehensive resource for manufacturing intelligence and assembly expertise. You too can realize superior yields and higher returns in your assembly processes.

Manufacturing engineers consistently and continuously include Applifast at the research and development stage through to final assembly for tooling and fastener expertise. Quality critical and safety critical fastening solutions and assembly tool management programs from Applifast ensure improved manufacturing processes through our attention to detail and uncompromising focus on efficiency, productivity, and overall customer satisfaction.

Bus & Coach

Manitoba companies are developing efficient transport as they continue to supply more than a third of the North American bus market. Winnipeg, Manitoba, Canada is home to the largest urban transit bus and coach manufacturer in North America. Applifast is a veteran supplier to OEMs, transit authorities, and their distributors and integrators.

Applifast’s extensive selection of OEM fasteners and installation equipment is trusted by transit authorities, coach lines, owner-operators, and collision/maintenance repair centres across all regions of North America.

Contact Applifast, located in the capital of bus and coach manufacturing, for quality OEM brand tools and fasteners.

Aerospace

Western Canada is made up of a highly developed aerospace industry. It is home to distinguished OEMs, MRO (maintenance, repair, overhaul), and service firms who serve hundreds of companies around the world. Applifast’s expertise in fastening, drilling, and assembly will be sure to bring your business confidence, quality, and reliability.

The aerospace sector of Manitoba includes designing, developing, and manufacturing composite aircraft components, assemblies, engine components, and accessories. Repair and overhaul of commercial aircrafts, advanced alloy turbine engines, piston engines, and accessories is also completed in Manitoba.

Local aerospace manufacturers and repair centres rely on the expertise from Applifast to deliver tools and tooling solutions compatible with the technicalities of today’s evolving aerospace industry.

Applifast serves the aerospace industry with fast turnaround on tool repairs completed by factory-certified technicians using only OEM parts. Applifast has compiled a wealth of knowledge and experience gained over generations that has proven invaluable to aerospace market leaders both locally and internationally.

FAQs

How does Applifast tailor its fastening solutions to different industries' unique requirements?

We combine expert knowledge with tried and true experiences of compliance, regulations, and standards across various industries. With a commitment to innovation and a focus on collaboration and customization, we provide tools and fasteners based on the specific application for industries including Truck and Trailer, Rail, Agriculture, Bus and Coach, Aerospace, and more.

What are some of the key challenges in the Aerospace Industry that Applifast addresses with its products?

In the Aerospace Industry, as with other industries, safety, reliability, and performance are paramount. Our products meet high performance requirements and can withstand extreme conditions such as high temperatures, pressure differentials, and vibration. Our Expert Solutions also meet demanding Aerospace specifications such as weight reduction, corrosion resistance, precision and tight tolerances, and compatibility with advanced materials.

In the agriculture sector, how do Applifast's solutions enhance equipment performance and durability?

From research and development to final assembly, our Expert Solutions enhance agriculture equipment performance and durability whether harvesting equipment, grain handling technology, or farm machinery such as tractors. By providing high-quality fasteners that enable equipment to function in rugged harsh environments, downtime is minimized and reliability is maximized. Customized tooling solutions also contribute to optimal performance in the manufacturing process of agriculture equipment. Our solutions will make agricultural operations more efficient by streamlining maintenance and repair processes as well.

What specific fastening technologies does Applifast provide for the Rail Industry?

We provide a range of fastening technologies tailored for the Rail Industry to ensure the safety, reliability, and efficiency of rail infrastructure. Our fasteners have proven themselves repeatedly whether used in gauge plates or insulated joints for tracking applications and diamonds or RBM frogs for crossing applications. Contact our trusted advisors to discuss your specific application and the best-fit fasteners for your job.

How does Applifast support the evolving needs of the bus and coach manufacturing sector?

Our extensive selection of OEM fasteners and installation equipment is trusted by transit authorities, coach lines, and collision/maintenance repair centres across all regions of North America. Special swivel heads and nose assemblies for fastener installation, tool torque audits, and T-handle drills for floor and decking applications are a few examples of our ingenuity being used every day as a vital part in evolution of bus and coach manufacturing.

Applifast Assurance promises you:

- Expert Knowledge; we know what we are talking about

- Quality Products; we stand behind our industry global brands

- Competitive pricing; we understand the importance of value, budget, and deadlines

- Reliable Service and Support; you can rely on us to do what we do best: help you

- Trusted Advisors; the Applifast name represents integrity and dependability.