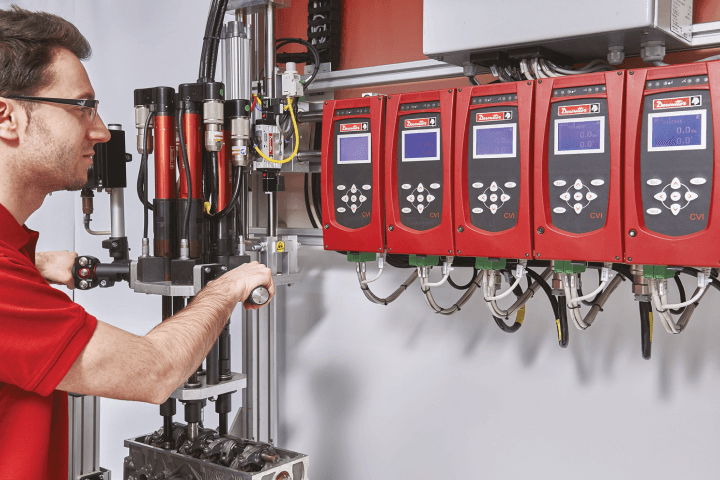

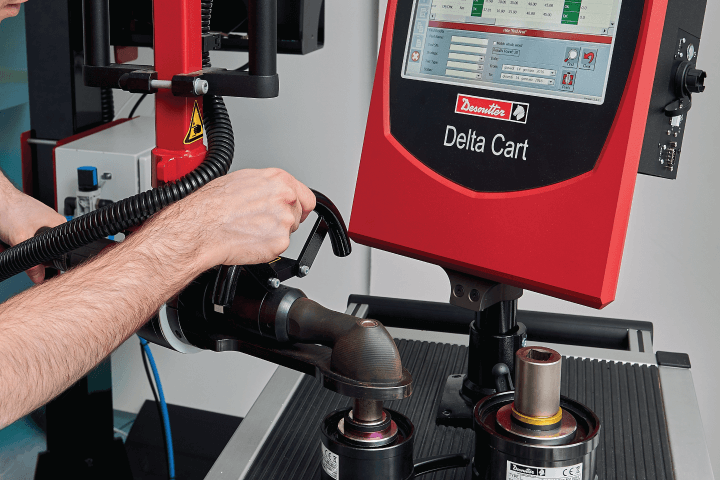

Preventative Maintenance

Get a Safe, Traceable Tightening Process

The Applifast Service Team has over 40 years combined of accredited knowledge and expertise.

Safety and Traceability of Your Tightening Process

- Wide Torque Range Capabilities in Compliance with ISO 17025 Devices

- Maintenance & Adjustment of Equipment

- Verification & Calibration

- Certificate

- Schedule Annual P.M. & CAL

The Thorough Service Our Experts Will Provide:

- Incoming Report

- Tool Disassembly

- Diagnostic Test

- Clean Tool

- Repair (if required*)

- Reassemble Tool

- Test Tool

- Calibrate or Verify

Calibration is Key to Get a Safe Traceable Tightening Process

- Less Rework

- Reduced Risk of False ‘OK’ Results

- Fulfillment of ISO Requirements

- Maintain Records in Case of Liability

Find out more about our service and maintenance support by contacting us.

Service & Maintenance