Fastening & Rivet Technology

In theory, a fastener is a device used for attaching one item to another. With the industry’s safety practices, a manufacturer or repair facility is held accountable for each fastener used to produce their products – the method in determining the specific tool or fastener to achieve a consistent clamp force can be complex and overwhelming.

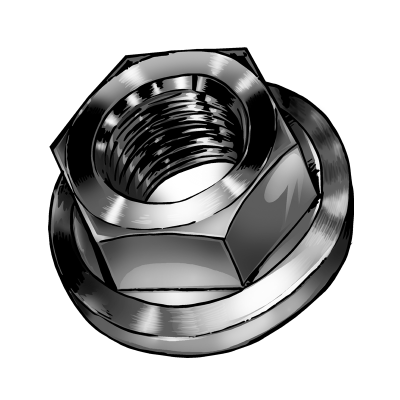

Each fastening challenge requires a unique practical solution, whether it be in the form of lock bolts, threaded inserts, blind or structural fasteners, or the use of anti-vibration threaded nuts. You can count on Applifast to deliver superior fastening expertise, complete with documented shear and tensile strengths, for an unmatched, vibration-resistant fastening solution that is safe, efficient, and cost-effective.

We are partnered with top tier rivet and fastening manufacturers and are honoured to be recognized as the preferred partner of HUCK® for Western Canada.

With our diverse range of installation tooling, we can accommodate your specifications.

- HuckBolts®

- Structural Blind Fasteners

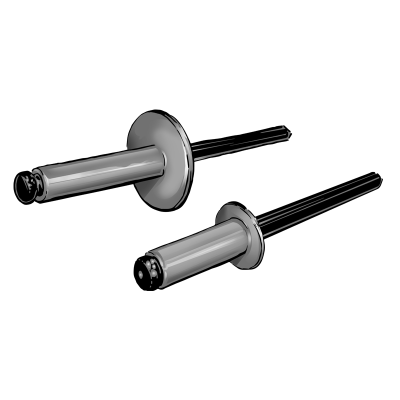

- Blind Rivets

- Threaded Inserts

- Wire Thread Inserts

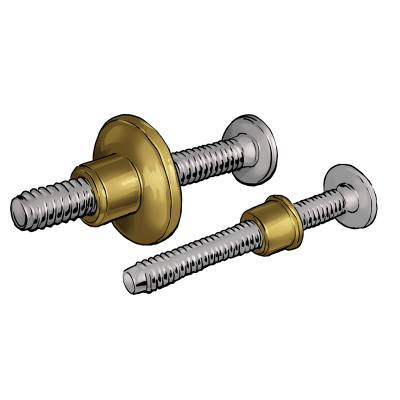

- Lock Bolts

- Speed Fasteners

- Self-Piercing Rivets

- Open & Closed-End Rivets

- Structural Rivets

- Critical Application Fasteners

- Thread Repair Kits

- Rivet Kits

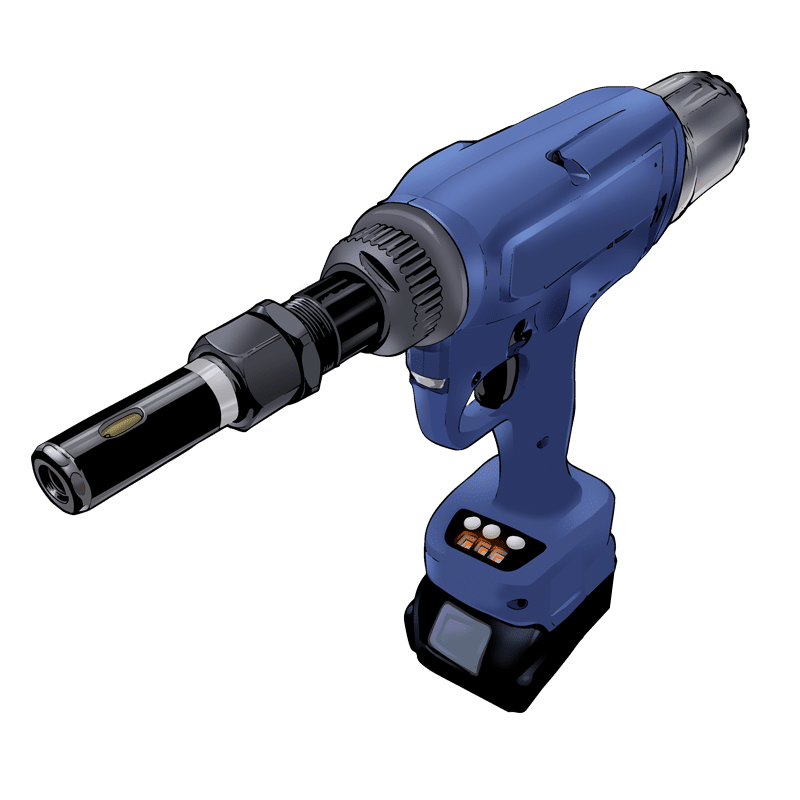

- Pneudraulic Riveters

- Huck Guns

- Cordless Riveting Tools

- Manual Tools

- Hydraulic Installation Tools

- Hydraulic Power Units

- Threaded Insert Installation Tools

- Nose Assemblies

- Mandrel Kits

Lockbolts are two-piece fasteners consisting of a hardened metal pin and metal collar which swages into the grooves of the pin. This forms a specific measured clamp force to hold assembled parts together.

Structural blind rivets are one-piece fasteners which are made from two assembled components including a pin and a sleeve. They can be installed with access to only one side of the material.

Mainly used in applications where there is no access to the rear (blind side) of the joint. Simplify assembly, improve appearance, and reduce costs.

Blind threaded inserts and studs have been engineered to meet the rigorous demands of all industries. The term ‘blind’ is used to describe these products because the operator installing these inserts and studs has no need to ‘see’ the backside of the application.

Can’t find what you’re looking for? We may have the solution for you from prevailing torque nuts to sealing fasteners and speed fastening including Avdel® Briv®, Avdel Rivscrew®, Avdel Chobert®, Avdel Grovit®, Avdel Avtronic®, Avdel Avsert®, and Avdel Avlug® fasteners.

We supply a wide range of fastening tools – battery, pneumatic, manual, and accessories for your fastener installation requirements so you can manufacture with confidence.