Tooling

Enquire about your Applifast Account

Start benefitting from expert advice to streamline your manufacturing processes.

With fastening technology, nothing should be left to chance, from conceptual design to the finished product, every design is significant and must be made with the end result in mind. Different materials and different applications combined with stringent specifications all require the definition of particular tools and fasteners. Applifast offers an extensive range of installation tools to meet your assembly requirements.

Our assembly tools feature a broad selection of clutch and motor options, covering a wide range of torques at varying speeds. Coupled with a diversity of attachments and throttles, these tools are suitable for an infinite number of applications.

Our in-depth understanding and proven expertise allows us to cover your every tooling need.

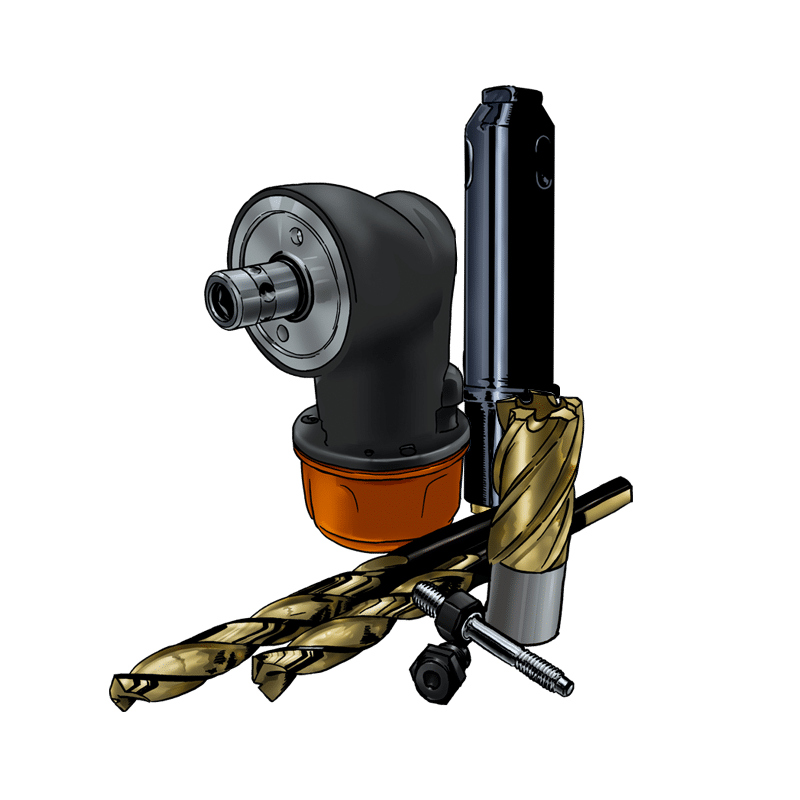

A hardened metal tool that is used to cut, shape, and remove material by means of machining tools as well abrasive tools like grinders, trimmers, and oscillating tools.

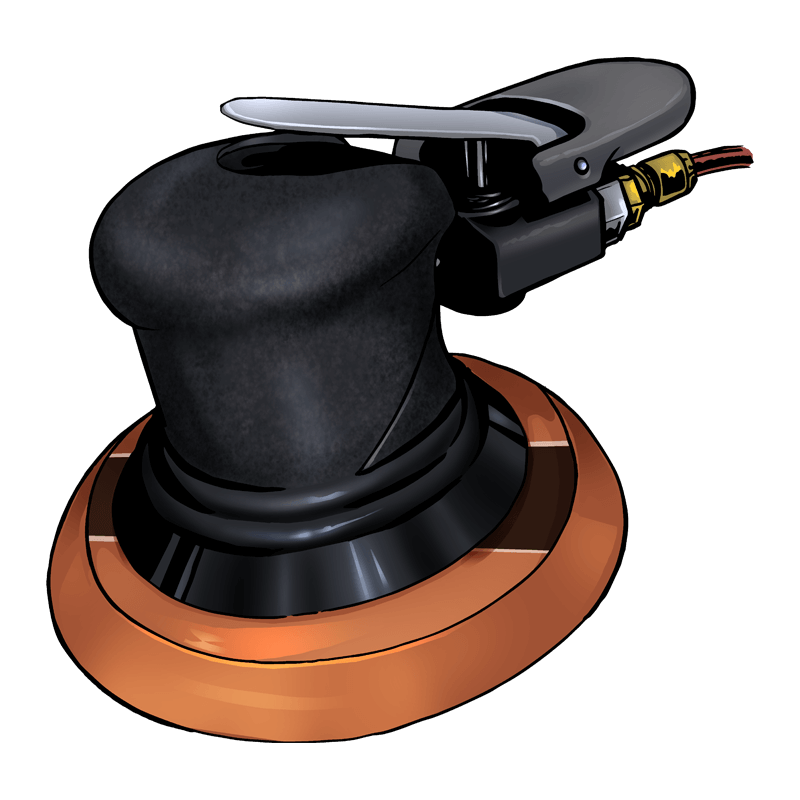

A correct tool – sanders and polishers, with the right abrasive will grind, blend, sand, and finish your application while optimizing operator safety.

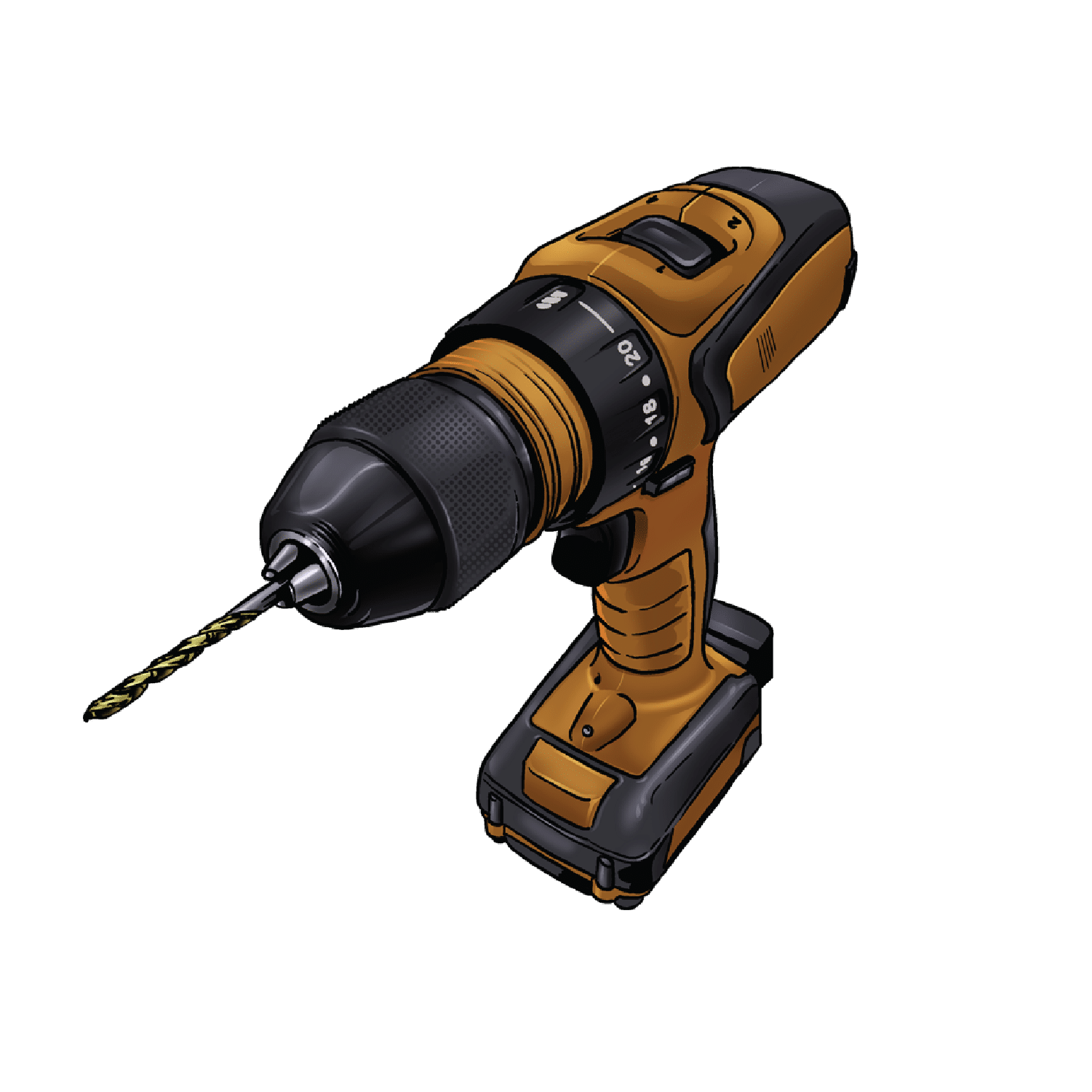

Drills are used in a wide range of applications. We have you covered with multi, angle, pistol, straight, battery, feed drill, and the accessories to compliment each drill type. All our drills offer ergonomic features to provide maximum comfort during operation.

We supply a wide range of fastening tools – battery, pneumatic, manual, and accessories for your fastener installation requirements so you can manufacture with confidence.

Powerful, professional-rated tools utilizing a unique design to transfer power, resulting in an efficient installation of rivets.

A large selection of gauges, airline accessories, tool balancers, sealants, and much more.