Achieving Excellence Together

Let us put 50 years of experience to work for you.

Since 1974, Applifast has remained a world-class leader who supplies high-quality goods, enhances product design, and streamlines assembly practices for diverse manufacturing, commercial, and industrial applications to ensure our customers thrive and grow.

We will help you find the right tools and fasteners for your job, provide tool service, and problem-solve your assembly processes.

We deliver value making you a stronghold within your industry now and in the future.

Expert Solutions

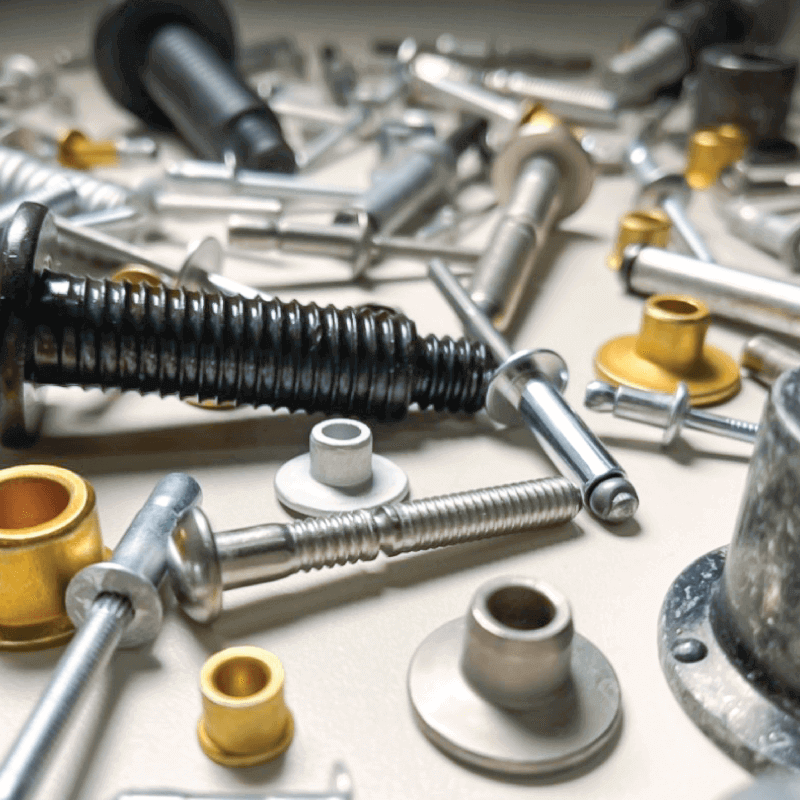

We are not just another vendor, we are your Industry Partner with practical strategies designed to increase your efficiency and productivity.

Applifast’s in-depth knowledge of threaded inserts, structural fasteners, lockbolts, blind rivets, installation tooling, and advanced fastening systems are relied upon by manufacturing engineers and production managers in many industries.

Every product, collaboration, and service is built on the demand of uncompromising quality.

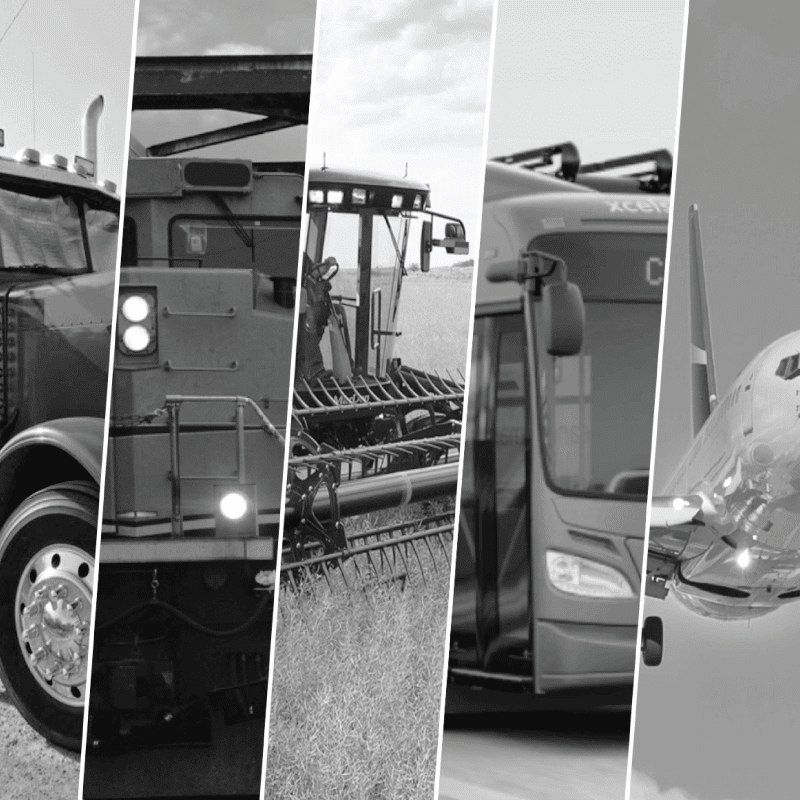

Industries

We pride ourselves as a progressive company who tirelessly researches manufacturing industries for advancements and trends to provide our clients with the latest innovations and quality performance results.

Many OEMs of truck bodies, semi-trailers, bus/coaches, RVs, aircraft, marine/boats, agricultural equipment, electronics, fleet vehicles, rail transport, mining, heavy equipment/construction, and all types of dealerships, repair/service shops and commercial trades have loyal and lasting partnerships with Applifast.

Brands

Work with Industry Partners who are invested in your success. Applifast has formed loyal relationships over decades of trust and confidence with many world-class vendors and global supply networks.

When quality and reliability matter, Applifast gives you the peace of mind of doing it right the first time.

Before any brand is recommended under the care of the Applifast team, the company is thoroughly researched to ensure it meets all governing regulations and guidelines in respect to best business practices, manufacturing processes, environmental impact, and ethics.